PROJECT DETAILS

Location:

Coolac, NSW

Product:

40kL Kubota K-HC-T to subsurface irrigation

Capability:

Consult, design, and construct STP

The Coolac Service Station is a new development on the Hume Highway requiring a wastewater treatment solution. True Water was engaged to assess the project requirements, site restrictions and government regulations and design a solution. As the development is in a remote area and not serviced by municipal infrastructure, an onsite sewage treatment system was required. True Water designed, manufactured, installed and commissioned a site specific sewage treatment system for the service station. It manages the wastewater generated by every aspect of the development. Along with the Mobil service station, there are several fast-food outlets, public amenities, laundry, and even a dog park. Modern environmental standards and aesthetics also needed consideration.

We worked closely with project engineers Allspec & Partners on this service station. Our initial brief was the design and documentation of the system for the council application. Many projects require adjustment to the design as they progress and this one was no different. The design of the disposal area was reconfigured four times to fit in with the project’s progression and address constraints. Council approval went smoothly with the in-depth information provided by True Water’s consultants.

True Water’s extensive history with service station wastewater systems was important in delivering this project. Service stations have high effluent strengths and variable loading rates. This site was no different and had restricted space available. The need to install the system close to the service station entrance meant any solution had to be odour free, safe for the general public and have minimal visual impact.

Specific challenges for service station wastewater treatment

Wastewater treatment plants at highway service stations are commonly undersized or overloaded. Increasing traffic, greater numbers of visitors, or expansion of the facilities can all add to this. Additionally, stricter regulations on discharge licensing by the Environmental Authority may warrant an upgrade to an existing system to meet new standards. Specifically, the difficulty in complying with ammonia and BOD limits.

Service stations generate highly concentrated wastewater due to the provision of fast food outlets, trucks stops, laundry facilities and amenities. The wastewater is characterized by highly variable flows, high ammonia content and high FOG (fat, oil & grease) content due to catering and food preparation. There are various tried and tested methods for treating service station wastewater. The most suitable method will depend on the unique requirements of the project itself. Grease management and the removal of emulsified oils must be considered before any biological treatment step. In addition to consent standards, site requirements and limitations must be taken into consideration.

As a result, many systems that currently treat service centre wastewater are not adequate for the job. Flow rates and effluent strengths are too extreme for domestic type systems which leads to shorter working life. Packaged plants are normally bulky and unsightly with high maintenance costs. Reliability is always a concern with packaged systems as well.

Project specific design features

True Water chose a 40 kilolitre Kubota K-HC-T as the best wastewater treatment solution for the Hume Highway project. Years of Research & Development by Kubota has produced a very well designed and engineered system. This system offers the excellent quality and reliability needed for a modern service station. Importantly, the modular system becomes almost invisible when installed below ground and is not accessible to the general public.

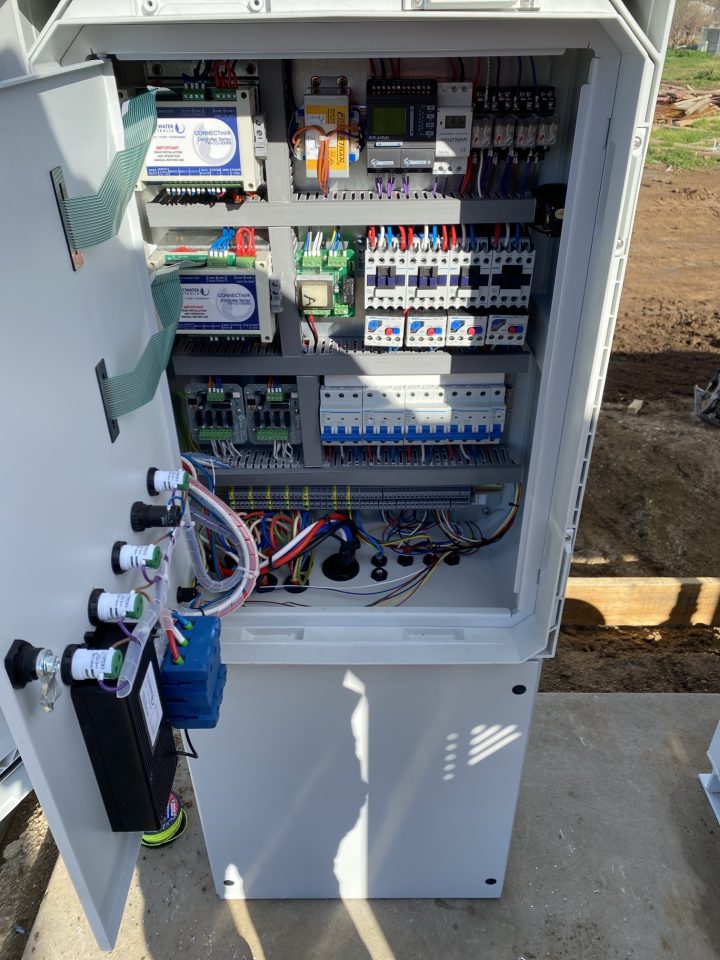

The treatment system and supporting components are manufactured off site and then transported to site for installation. As a result, the time required on site for installation is reduced allowing. This allows for a speedy project delivery while ensuring quality. True Water completed the installation in two stages to allow for additional flexibility in coordinating with the builder. We completed the two separate irrigation and disposal areas first. Then, we installed the treatment plant and control systems once the builder was ready to connect to the infrastructure.

The subsurface irrigation for the grassed front verge area will keep it looking lush and green all year round. The treated water from the Kubota system is so clean that it is perfect for maintaining lawns and saving water. In addition, the visual footprint of the system is kept to a minimum.

True Water are installing more systems for service stations than ever. Our compact, modular, state of the art systems combine simple process with high quality treatment. Importantly, this provides the perfect treatment solution for the unique requirements of a roadside petrol station.

Contact our team about your project today.