PROJECT DETAILS

Location:

Ulan, New South Wales

Product:

20kL Kubota K-HC-R

Capability:

Consult, design. and construct STP

True Water successfully tendered to provide a prefabricated wastewater treatment plant for the Surface Operations facilities for Glencore’s Ulan Mine. The existing STP was around 40 years old and had come to the end of its operational life. As a result, a replacement system was required.

The newly installed Wastewater Treatment Plant will provide a higher level of treatment. Consequently, this will meet the environmental standards and deliver long-term compliance. The system provides wastewater treatment for the mine administration facilities. It’s located on the western corner of the mine site. It processes domestic waste from onsite amenities including toilets, showers, and kitchen/dining areas.

Located central west of NSW, the Ulan complex is one of the most established coal mining operations in Australia. True Water has installed and continues to maintain Wastewater Treatment Systems for a number of Glencore’s mining sites. As a result of the successful tender process, True Water undertook the design, construction, installation, and commissioning of the new prefabricated Kubota Wastewater Treatment Plant to upgrade the Ulan Mine site system.

Meeting the requirements of the client

The original system treated up to 10kL of wastewater per day. To clarify, this is insufficient capacity for the current wastewater flow. Designed and installed in the early 1980s, the technology has been superseded. The packaged treatment plant treated raw sewage using the suspended growth-activated sludge process.

The original packaged treatment plant was an above-ground system that remained unchanged after its installation. The steel tank system had rusted out. As a result, it was no longer treating the wastewater to the required level. For this project, the client needed a robust replacement STP which that can operate with little intervention. In particular, without the need for technically trained staff.

After completing a site assessment and desktop research, True Water found the Average Dry Weather Flow (ADWF) ranged from 6 to 8kL. The Peak Wet Weather (PWWF) being 13kL a day. The Consultancy team determined a 20kL/day Kubota MBBR Treatment Plant as the ideal system replacement.

The advanced tertiary treatment provided by the Kubota MBBR Treatment Plant produces Class B treated water. Importantly, this means it is suitable for disposal into the existing evaporation ponds. Therefore there is no requirement to install additional effluent disposal structures. If operations increase or the ponds are no longer viable, the standard of effluent from the system meets the requirements for future reuse, including irrigation.

The original sewage treatment system utilising a suspended gorwth-activatied sludge process at Ulan Mine was undersized and performing poorly.

A smooth transition from old to new

The scope of this project required the retention of the supporting infrastructure and dispersal ponds. In addition, to ensure no loss of operation time, it was important for the changeover from the existing system to the new treatment plant to be completed quickly.

Firstly, we installed the new system next to the original infrastructure to allow a smooth transition. The lightweight, fiber reinforced plastic Kubota systems are designed to be self supporting and can easily be installed below ground. The compact system was installed in the tight space without disturbing the infrastructure to be retained. Once the new treatment plant and control systems were in place, the now defunct STP was decommissioned and removed.

Throughout the process, True Water worked closely with the team from Glencore to ensure the on-site staff would have a clear understanding of how the new system would work. A key benefit to True Water’s solution is its simple and efficient technology. The systems requires very little day-to-day maintenance or chemical dosing.

On-site staff undertook training in simple system maintenance including sampling. True Water will remotely manage the new system and provide a quarterly service in accordance with government regulations.

Meeting the challenges of the site

Due to the nature of the project, Glencore needed True Water to deliver the new wastewater treatment system in a short timeframe. Additionally, we could not interrupt the regular operation of the Surface Operations facilities. True Water pre-manufacture most of their systems before delivery to the site. This aids in a quick and stress-free installation. Pre manufacturing in our workshop provides the ability for a quick and quality installation occur. As we already had a Kubota system in stock, all we had to do was customize it for Ulan Mines.

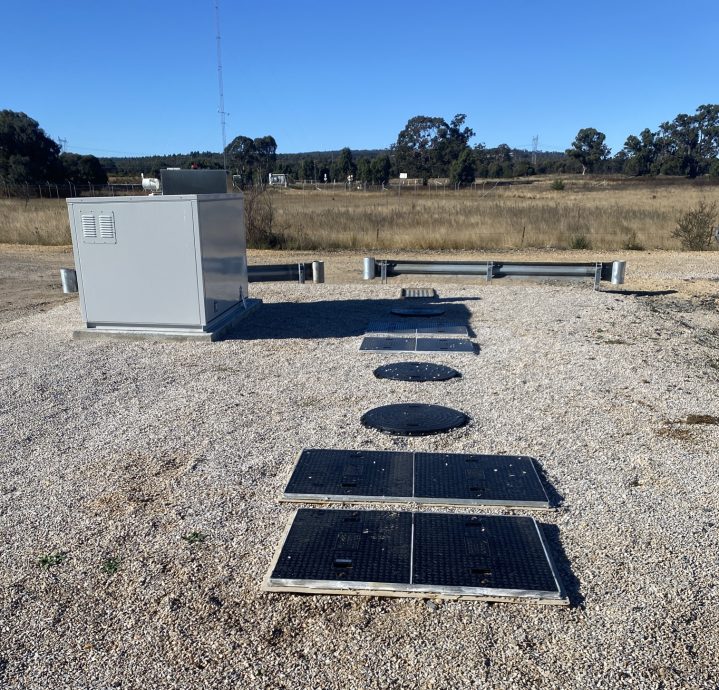

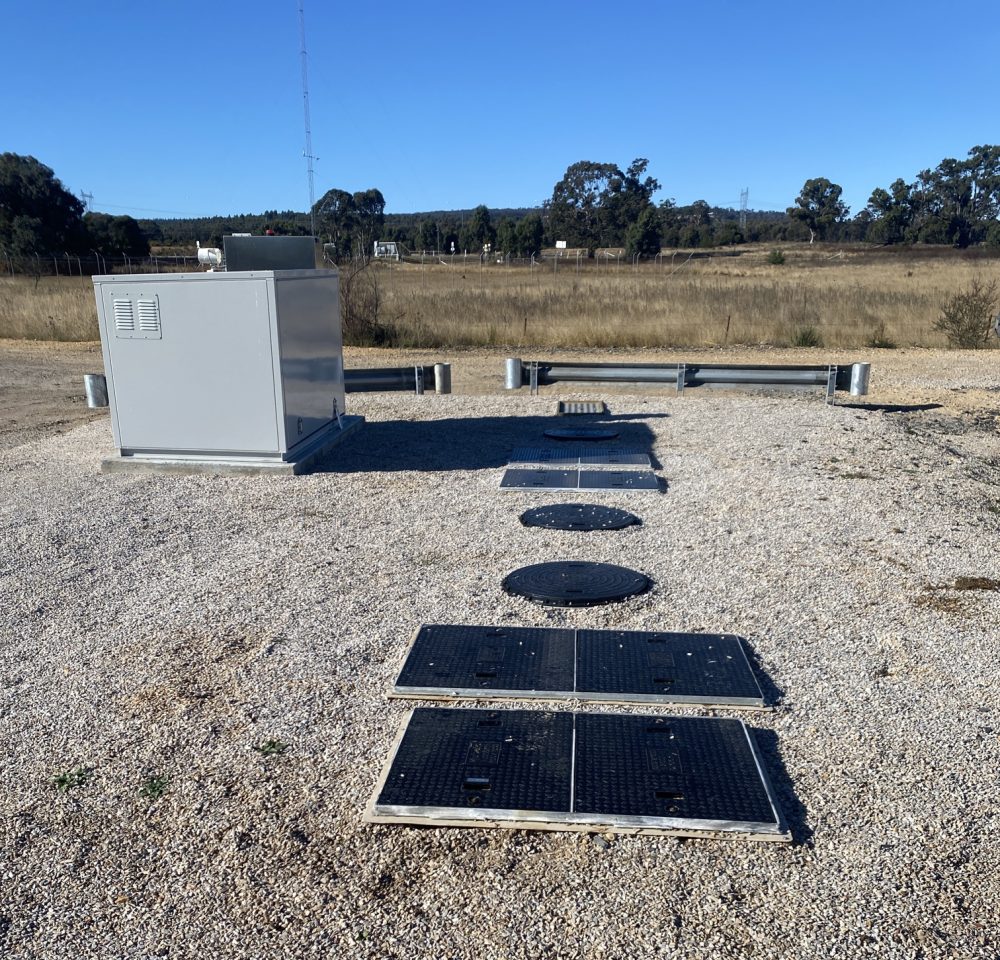

Surface water and groundwater were potential issues for the long-term compliance of the site. The existing STP was regularly surrounding by standing surface water. To combat this issue, True Water installed the treatment tank to sit above ground level. We then built up the soil to create a new ground level at the height of the gas tight inspection lids. This keeps the access covers above any surface water with the control system and blowers installed at the same height.

Higher quality treatment for system upgrade

True Water worked with Glencore to meet the site requirements for the Ulan Surface Operations. As a result, the successful delivery a state-of-the-art wastewater treatment system is complete. Our design utilises advanced technology to provide reliable and high-quality treatment. The system now easily meets the variance inflow volumes and concentration at all times.

Most importantly, the design accommodates future additional flows. The system treats the wastewater to the standard required for future irrigation if needed. Furthermore, the Kubota system meets international quality compliance standards whilst providing operational security. This is exactly what Glencore required.

The prefabricated Kubota system installed by True Water upgrades the wastewater treatment infrastructure at Ulan Mine Surface Operations. Importantly, it provides a new and modern fit for purpose solution that will stand the test of time.

Contact True Water today to discuss your system upgrade requirements.