PROJECT DETAILS

Location

Lake Awoonga, Benaraby QLD

Product

40kL K-HC-T STP

Capability

Consult, Design, and Construct STP

The Gladstone Area Water Board (GAWB) own and operate the Sewage Treatment Plant (STP) at Lake Awoonga. With over 35 years of operation, the existing STP servicing the Lake Awoonga Caravan park and nearby Gladstone Area Water Board (GAWB) Depot was deemed to have reached the end of its operational life. The system required significant attention and management to maintain treatment processes. As a result, they had ongoing difficulty achieving compliant performance. Due to the increasing operational burden and the decline in compliant performance, a replacement treatment system was sought.

GAWB undertook an extensive tender and assessment process to find an appropraite solution. They investigated many different treatment solutions to find the best outcome for the project. Performance history, company background and operational practices were all taken into account. GAWB chose True Water Australia to design, manufacture and install the new treatment system. Ongoing operational management will also be provided by True Water.

The Client – Gladstone Area Water Board (GAWB)

Established in 1973, the Gladstone Area Water Board ensures the short and long term water needs of current and future customers are met in ways that are environmentally, socially and commercially sustainable. GAWB achieves this through thoughtful forward planning for the region’s needs. Their team develops, operates and maintains the infrastructure required in a sustainable manner. All while minimising the impact its operations have on the environment.

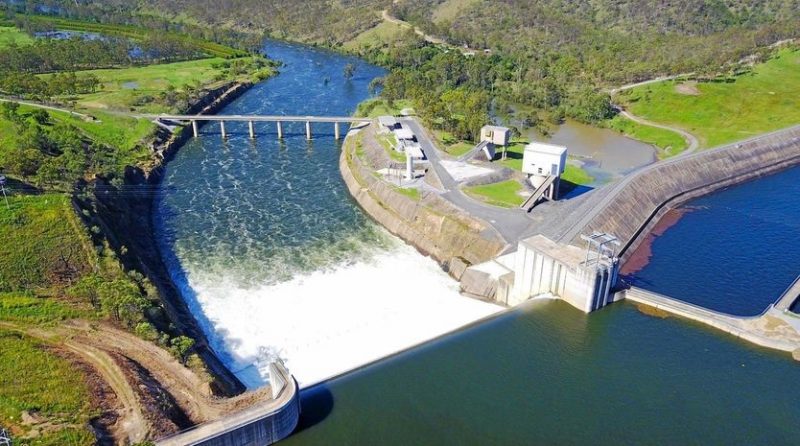

GAWB owns and operates Awoonga Dam on the Boyne River. Their network of delivery pipelines, water treatment plants and other bulk water distribution infrastructure, supplies up to 78,000 Megalitres of potable water to the Gladstone region each year.

Replacement of existing Sewage Treatment Plant for Water Utility

Lake Awoonga is located approximately 30 km south of Gladstone, Central Queensland. The STP currently services the Lake Awoonga Caravan Park, a workshop, 5 residential houses, a kiosk, and a toilet block at the picnic area located at the boat ramp. The land set aside for sewage treatment infrastructure is north-west of the caravan park in a restricted access area. Two designated land application areas are to the south of the treatment plant. Also included in the treatment cycle is a wet weather storage dam.

The existing STP servicing the needs of the Lake Awoonga area had reached the end of its operational life. The system required significant attention and management to maintain treatment processes and had ongoing difficulty achieving compliant performance. Due to the increasing operational burden and the decline in compliant performance, GAWB required a replacement treatment system.

The True Water Design & Consultancy team proposed a complete wastewater treatment solution. This involved installation of a new Kubota STP and reuse of the treated water via alternating irrigation to land application areas. Upgrading the existing wet weather storage was also included. GAWB selected True Water to provide the new infrastructure as they proposed the only solution that met all of the project conditions. In particular the site constraints, longevity, life cycle management and the potential future increase in demand requirements were all met.

Key Project Considerations for Lake Awoonga Sewage Treatment

The GAWB process involved the assessment of key elements of consultancy and regulatory approval by GHD Engineering Consultants. The system is required to manage daily maximum flows of 40kL. Hydraulic flows can vary significantly with seasonal influxes of visitors. Therefore, the STP must be capable of reliably managing and treating fluctuating flow volumes and varying quality.

The tender design indicated an above ground containerised or similar rotating biological contactor packaged plant. True Water identified the Kubota treatment system would be capable of providing improved project outcomes.

Operational security is vital for this project with the STP located near the main potable water source for the Gladstone Region. A 40kL Kubota sewage treatment plant provided the highest level of reliability and operational security, with minimal operational cost burden. The design also allows for future expansion of the treatment capacity with the ability to add additional modular units.

The Lake Awoonga STP must conform to the GAWB and the Qld Department of Environment and Science operational expectations. It needs to be highly reliable, including contingency and safeguards to ensure continuity of service at all times. Particularly during peak usage and power outages.

In accordance with the GAWB’s operational mandate, the infrastructure must not negatively impact the environment. This aligned well with True Water’s vision for all STP’s to provide a neutral or beneficial impact to the environment.

World leading technology provides the simplest solution

Kubota Corporation mass produce three series of onsite STP’s under ISO:14001 & ISO:9001 certification. The systems can be applied to various applications to provide certainty through proven operation and surety of manufacture. True Water’s consultants consider the scale of the project, the strength of influent and the quality of treated water. The most suitable STP is selected and the size and scale of the plant is confirmed. A Moving Bed Biological Reactor (MBBR) type treatment plant was chosen as the best fit for the Awoonga Dam specification. The final design demonstrates a best practice outcome for a commercial sewage treatment plant. This means the system balances technical specification, operational performance and technology complexity to achieve compliance treatment performance. All while providing a long term, financially sustainable solution.

Both Gladstone Area Water Board and True Water have a keen eye for detail and we shared many core values with a focus on quality, performance and value for money.Looking back the design phase was a highlight, working with Gladstone Area Water Board we were able to identify major design challenges. We had long discussions about the challenges relative to the site and within the concept design and spoke in detail about the best outcome.We then we focused on designing true benefits into the system.T

his happened in each part of the infrastructure, the pipelines, the pumpwells, the Sewage Treatment Plant, control system and irrigation system. In each part of the project we were able to maximise efficiency and limit management requirements. We also saved some serious money along the way which I know Gladstone Area Water Board was very happy about.

James Mahoney, True Water Australia, Managing Director

Delivering a sewage treatment solution for Lake Awoonga

Kubota Corporation manufactured the MBBR STP in Japan. Global manufacturers produced all components (including controller, pumps and blowers) to Kubota Corporation’s design specifications. Mass production, standardisation, and uniformity provide security of operation. This allows Kubota to provide a strong warranty covering the entirety of the STP. They also offer a Performance Guarantee covering operation and performance.

True Water fabricate and assemble all additional components including STP controller, telemetry, airlines, transfer piping and pump sets. Completing these tasks in our workshop prior to dispatch to site minimises risks associated with onsite fabrication. Installing the STP below ground eliminates visual and odour impacts. This also minimises temperature fluctuations and reduces deterioration caused by exposure to weather.

The Lake Awoonga STP project included multiple life cycle stages; infrastructure design, project delivery and infrastructure management. GAWB and True Water held weekly meetings to ensure the project remained on track with the project objectives satisfied during each stage of the process.

A key challenge of an infrastructure project is the coordination of multiple disciplines, for a sewage infrastructure project that’s especially true. For instance, throughout the design and delivery stages, many specialties needed to be coordinated: mechanical engineering, electrical engineering, telecommunications, plumbing, specialist irrigation design, civil works and of course wastewater engineering expertise.

New treatment system operational at Lake Awoonga

The new sewage treatment plant at Lake Awoonga is now operational and producing excellent water quality results. As part of True Water’s ongoing commitment to the project, the Works & Services group is conducting ongoing training on site in the maintenance and operation of the plant. An official opening held with industry and government representatives highlighted the quality of the project. This included guided tours of the main treatment compound and all of the supporting infrastructure.

“We have a responsibility to deliver high quality infrastructure to the people of Gladstone, and we have achieved that.

With due diligence and after a careful selection process, we appointed the project to True Water Australia. Their partnership as the Australian distributor for Kubota products, combined with their team’s knowledge and expertise in delivering sustainable and effective installations meant they were the right fit for our project.”

Darren Barlow, Gladstone Area Water Board, CEO

True Water launches new Kubota sewage treatment system at Lake Awoonga

Utility Magazine -5th Feb 2020:

“The successful collaboration between True Water Australia, Kubota Corporation and the Gladstone Area Water Board (GAWB) has culminated in the installation of the latest world leading infrastructure to service the needs of the area.”