PROJECT DETAILS

Location:

Toowoomba, QLD

Product

500kL K-HC-R STP

Capability

Design and Construct STP

Wagner Corporation is a family-owned Australian company with a focus on property, infrastructure, and sustainable development. With a family history in Queensland dating back to 1856, the Wagner family is considered a major contributor to the state’s regional development.

The Wellcamp Airport and Business Park, developed by the Wagner family and opened in 2014, is a 500-hectare integrated facility located near Toowoomba. The precinct is intended to become the business hub of Toowoomba and regional Queensland. It includes logistics, manufacturing, and agricultural processing facilities.

Wellcamp Airport is the first greenfield public airport built in Australia in 50 years with significant private investment. This state-of-the-art facility significantly enhances the connectivity and economic potential of the Toowoomba region. It serves as a key infrastructure asset, supporting passenger travel and freight services.

Wagner’s developed Environmentally Friendly Concrete for use in the construction of the airport. This clean technology offers ultra-low carbon concrete solutions with unique durability and performance. It ensures excellent structural integrity and the highest level of sustainability.

Sewage treament solution for airport precinct

The development is located approximately 15 kilometres West of Toowoomba, beyond existing sewerage service networks. Therefore, it required a custom designed Sewage Treatment Plant (STP). Wagners undertook extensive research and assessed all sewage treatment solutions and providers available in Australia to find the best outcome for their development.

The assessment took more than two years. It involved investigation into multiple treatment technologies, performance history, company background, operational practices and multiple site visits. Additional factors that were assessed included scalability, capital and operational costs, configuration and aesthetics (visual, odour and noise).

Wagners concluded that the only solution that would meet their requirements was the Kubota Sewage Treatment Plant STP with design, delivery and operation by True Water Australia.

“Wagners is a large family company based in Toowoomba, Australia. We needed the world’s most reliable, high-quality sewage solution for the Brisbane West Wellcamp Airport and Wellcamp Business Park. The Wellcamp Airport and Business Park offer world class infrastructure and facilities and have a focus on the highest environmental performance possible.

True Water Australia was chosen after discussions with each of the leading providers in Australia. We made this decision as True Water Australia displayed many of the traits that made Wagner’s successful, namely innovation, attention to detail, focus on quality, dedication and customer service. Wagners is extremely happy with the quality and performance of True Water Australia’s works and the Kubota STP.”

–Denis Wagner, Managing Director, Wagner Corporation

Key challenges of the project

The project posed several key challenges for effective sewage management. This included highly variable flows, staging requirements and high levels of trade waste.

The Wellcamp Airport and Business Park will be delivered over a period of several years across several stages. The STP needed the capability to be delivered in line with the staging requirements. This ensures the STP is always sized adequately for daily flows and reduces up front capital costs.

The development includes more than 250 industrial lots. While some pre-treatment will be performed, the STP must be capable of handling influent with contaminant concentrations beyond domestic levels. Hydraulic flows vary significantly with seasonal influxes of passengers. Therefore the STP must be capable of reliably managing and treating varying flow volumes.

The Wellcamp Airport and Business Park is essential infrastructure for the region and requires continuity of essential services. The STP must be highly reliable and include contingency and safe guards to ensure continuity of service at all times.

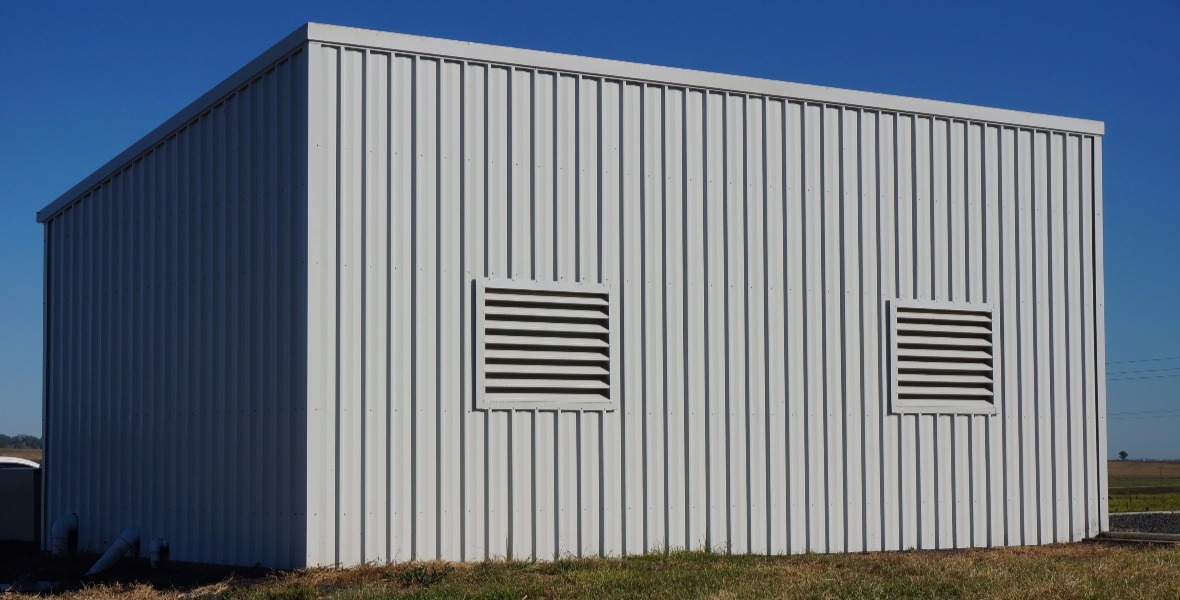

True Water designed and constructed a 500m3 Kubota K-HC-R Sewage Treatment Plant with Stage 1 providing up to 100m3 treatment capacity per day. The WWTP will be scaled in 50m3 stages to provide efficient and cost-effective sewage treatment and exceptional environmental outcomes.