PROJECT DETAILS

Location

Rollestone, QLD

Product

100kL K-HC-T STP

Capability

Design and Construct STP

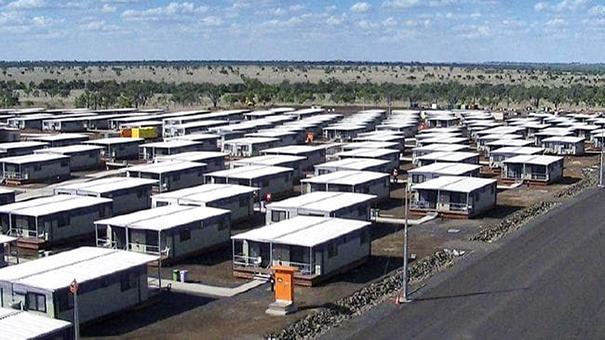

True Water were recently engaged to complete a full Sewage Treatment Plant (STP) replacement at Glencore’s Rolleston Mine Accommodation Village. It is located in the southern part of Queensland’s Bowen Basin, approximately 16 kilometres west of the Rolleston Township and 140 kilometres southeast of Emerald. More than 600 staff are currently employed at the mine which extracts coal for the domestic and export markets. The Accommodation Village provides housing and facilities for the mine staff.

The Rolleston mine is located in a remote area far from municipal wastewater treatment infrastructure. An on-site, reliable and high-quality STP is required to keep the mine and its various facilities running smoothly. True Water Australia had previously designed, manufactured, installed and commissioned a Kubota HCZ-50 sewage treatment plant to meet the needs of the Administration Complex for the Mine Infrastructure Area (MIA). With remote monitoring, onsite training of personnel and a servicing plan, the wastewater treatment system has been performing at a high standard and meeting all QLD Environmental Authority requirements for the site.

Providing an STP replacement as part of overall solution for mine

True Water were engaged to design, install and commission a replacement STP at the Rolleston Mine Accommodation Village. When the existing containerised sewage treatment system failed, a reliable upgrade was sought by Glemcore. A swift replacement of the existing system was required as the failed Pureplus Treatment Plant was not operating to specified treatment levels. Of course, this posed health and environmental risks.

The system being replaced was less than two years old. Although it had failed, there were components that were still in operational condition. It was important to retain and utilise as many exsisting wastewater treatment assets as possible to minimise the costs involved in rectification works. An assessment of site infrastructure was undertaken to evaluate the existing components for integration into the new solution.

From development of the mine through to today’s operations, Rolleston Open Cut has demonstrated their commitment to compliance with State and National environmental standards. This includes progressive rehabilitation of mined lands. In July 2018, Glencore received certification from the Queensland Government after rehabilitating 220 hectares of mined land.

The solution for Glencore’s mine accommodation village

Glencore looked for a STP replacement solution that can achieve quality and budget requirements. In addition, minimising operational costs throughout the infrastructure life cycle is key. It is vital that this includes operation, maintenance and monitoring. As part of their ongoing commitment to compliance with State and National environmental standards, it was important the solution True Water provided was of the highest quality and reliability. Glencore’s process included engagement of third party consultants and industry experts to inspect STP’s True Water have in operation in similar applications. This determined the suitability of the Kubota STP for the Glencore Rolleston site.

The primary project scope was to replace a relatively new system, with guaranteed STP reliability. Continuity of operation of the existing accommodation village being a key consideration. The Rolleston mine has also received government approval to extend its mine life beyond 2040. This will create an average of 84 full-time jobs over 10 years and once completed about 1200 full-time jobs. This could potentially double the requirements of the Accommodation Village. Therefore, the design needed to include potential to expand capacity to accommodate higher influent flow volumes.

“We’ve recently contracted True Water Australia to design, construct (through Kubota), supply and oversee both the installation and commissioning of a new Sewage Treatment Plant at Rolleston Coal for our 700 unit accommodation village.”

“During the tender process we found TWA’s technical knowledge, proven working STP systems elsewhere and compliance to government regulations to be far superior to other tenderers. This was proven through consistency in results, testing and reporting data supplied.”

James Bernstein – Project Manager, Glencore, Rolleston Mine, QLD

Wastewater management upgrade for Rolleston Mine

True Water designed and constructed a 100m3 Kubota K-HC-T Sewage Treatment Plant. It has the potential to expand capacity of the system in stages in line with demand. The Kubota STP provides a replacement for the old system, using biological treatment through a Moving Bed Bioreactor. This is contained within a single treatment train which includes no moving parts or pumps. A future upgrade would see the same system installed alongside the first stage. The expansion utilises shared infrastructure throughout including controllers, buffer storage tanks and treated water storage).

Kubota STP’s are manufactured under ISO and Internationals Standards accreditation for the treatment of wastewater. This provides uniformity and surety. Because the treatment plants are premanufactured, True Water can deliver large scale solutions in a short period of time. This ensures each wastewater system meets the specific requirements of the site while providing security to our client.

Once True Water finalised the design, Kubota undertook manufacture of the K-HC-T treatment plant. It was delivered to site approximately 14 weeks from the acceptance of the design and placement of the order. Once the STP arrived onsite it was a simple process to install the tanks, make final connections and backfill around the system. A process that took only six days, from delivery to operation.

The existing failed sand/media filters were removed with a portion of the existing infrastructure retained and re-purposed. By repurposing this infrastructure, True Water were able to significantly reduce the rectification costs. The assets proposed to be kept were inspected on site for suitability and structural integrity before being integrated into the new system.

The True Water/Kubota STP Solution

True Water is highly experienced in providing replacement solutions for failed or undersized commercial wastewater treatment plants with specific environmental considerations. We recently completed two system replacements on World Heritage listed Fraser Island as part of our wastewater treatment plant contract with the Queensland Government National Parks.

Eurong Rangers Station Sewage Treatment Replacement

Dundubara STP Rectification Works

True Water chose a Kubota system for the Glencore Rolleston Accommodation Village that would provide efficient and cost-effective sewage treatment. The STP produces a high quality of treated water and a high level of nutrient reduction, ensuring exceptional environmental outcomes. During the design and planning phases, all parties took part in a high level of communication to ensure that project timelines were met and continuity of service was guaranteed. The professionalism and organisation within the Glencore and True Water teams ensured the project was delivered on time and on budget.

“Their team are experts in all aspects of wastewater from pricing and design through to delivery and contract management. TWA have been extremely professional resulting in smooth sailing with all milestones met and delivered without issue or incident.”

James Bernstein – Project Manager, Glencore, Rolleston Mine, QLD